Chain Conveyors

Motridal manufactures drag chain conveyors for every industrial field: from low capacity chains to heavy duty high-capacity chain feeders and conveyors.

Motridal manufactures drag chain conveyors for every industrial field: from low capacity chains to heavy duty high-capacity chain feeders and conveyors.

These machines represent the most suitable solution for horizontal, inclined, or vertical transport of bulk materials, especially in the case of particular environmental needs or material characteristics (temperature, abrasiveness…). Motridal’s range of production includes both central chain and double chain conveyors, with forked link chains or round steel chains (for cleaning chains).

Motridal manufactures a wide range of central chain conveyors. The chain of these conveyors is made of drop-forged links in varying steel materials and alloys in accordance with the individual application. Chain links are casehardened and tempered for wear and impact resistance. Steel scrapers are welded to the chain links for material conveying. Steel scrapers are welded to the chain links for material conveying. The scrapers are “V-shaped” to allow for chain self-centering. This type of machine allows the conveying of material with horizontal and vertical paths simultaneously.

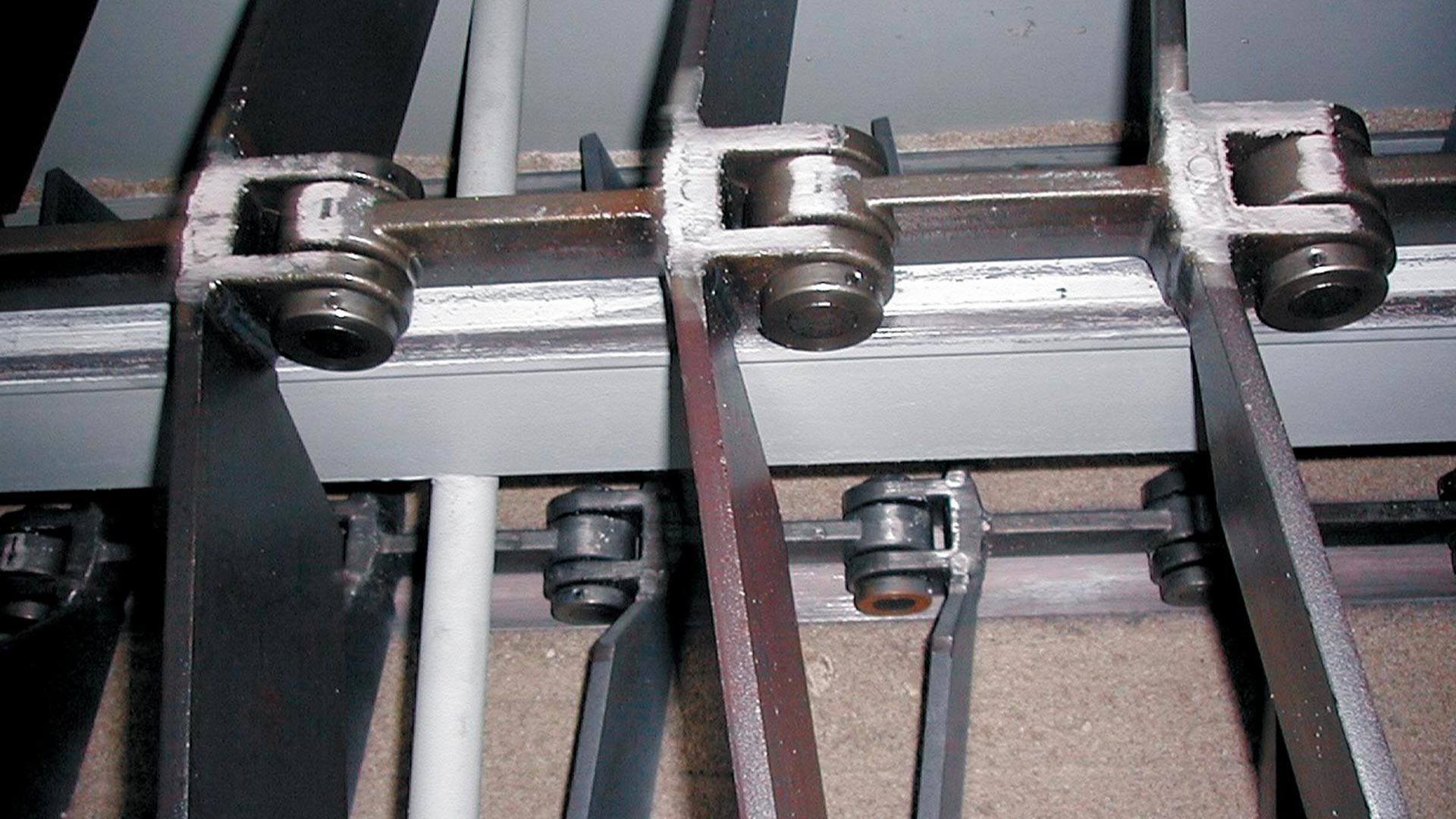

The size of double chain conveyors can reach up to 55”, thanks to the presence of two traction elements, which allow the use of longer scrapers. For these machines, Motridal uses specially designed casehardened and tempered drop-forged forked links. Flights are fixed by means of special pins to the chain links. The chain guides made in wear-resistant steel are bolted to the internal side of the conveyor casing for easy maintenance and replacement.

Cleaning chains are used to collect and recycle the material spilled from open conveyors (belt conveyors, pan conveyors, apron conveyors…) in order to reduce product accumulation underneath the conveyor and environmental pollution.These machines are built with standard components (round steel chains, standardized drive and tail wheels…) and they are adapted each time to the specific application.The use of standard components allows you to minimize the stock of spare parts, significantly reducing the costs associated with routine maintenance.

Submerged chain conveyors are usually positioned under the furnace outlets in order to collect hot ashes. The ashes are cooled by water and conveyed along the horizontal section of the conveyor; then, along the sloping section. Thanks to the slow speed of the chain, the water is drained and the material is conveyed outside.

Special-purpose chain conveyors allow for the possibility to convey material with slopes up to 90°. These type of conveyors are often used with a horizontal/vertical/horizontal configuration.

Chain conveyors are also used as discharging devices for silos and hoppers. In these conveyors the material is conveyed by the upper strand of the chain, thanks to a double bottom which separates the material from the return strand.

Download the Motridal brochure in PDF